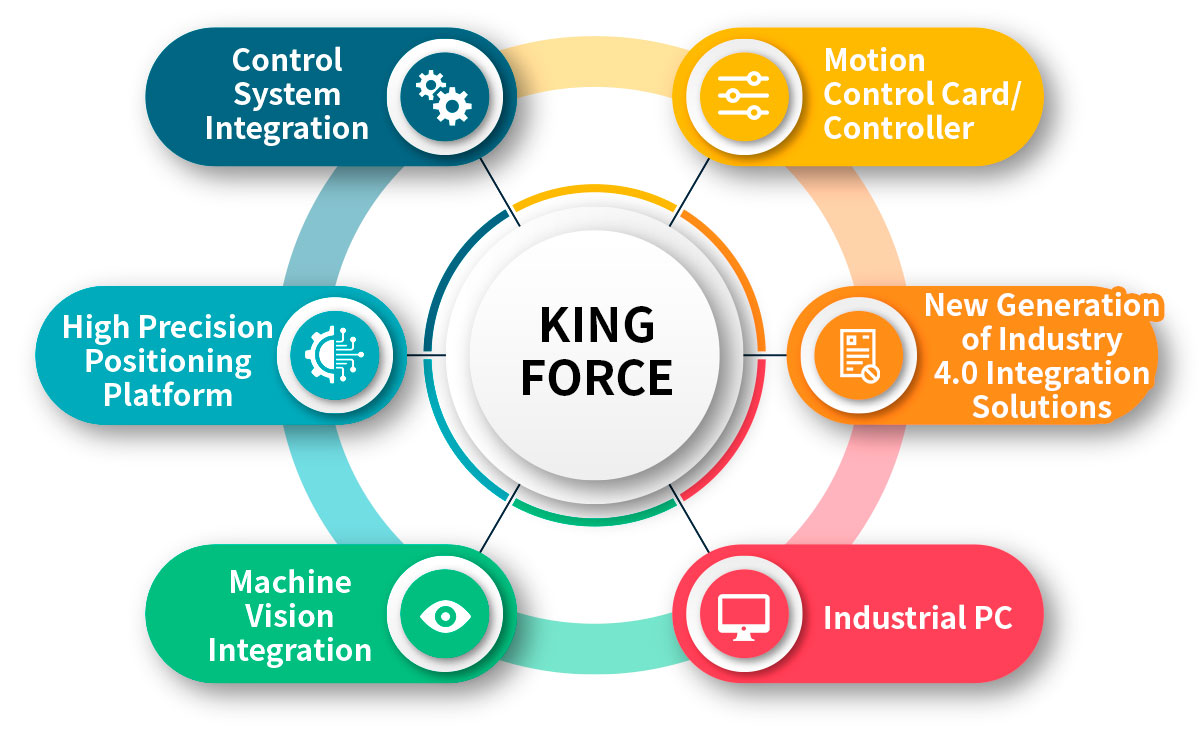

System Integration Solutions

Compact Precision Linear Module

- Simple assembly

- Achieve ±3um accuracy without linear encoder

- Lower cost (compared to traditional linear motors)

- Simple assembly

- Achieve ±3um accuracy without linear encoder

- Lower cost (compared to traditional linear motors)

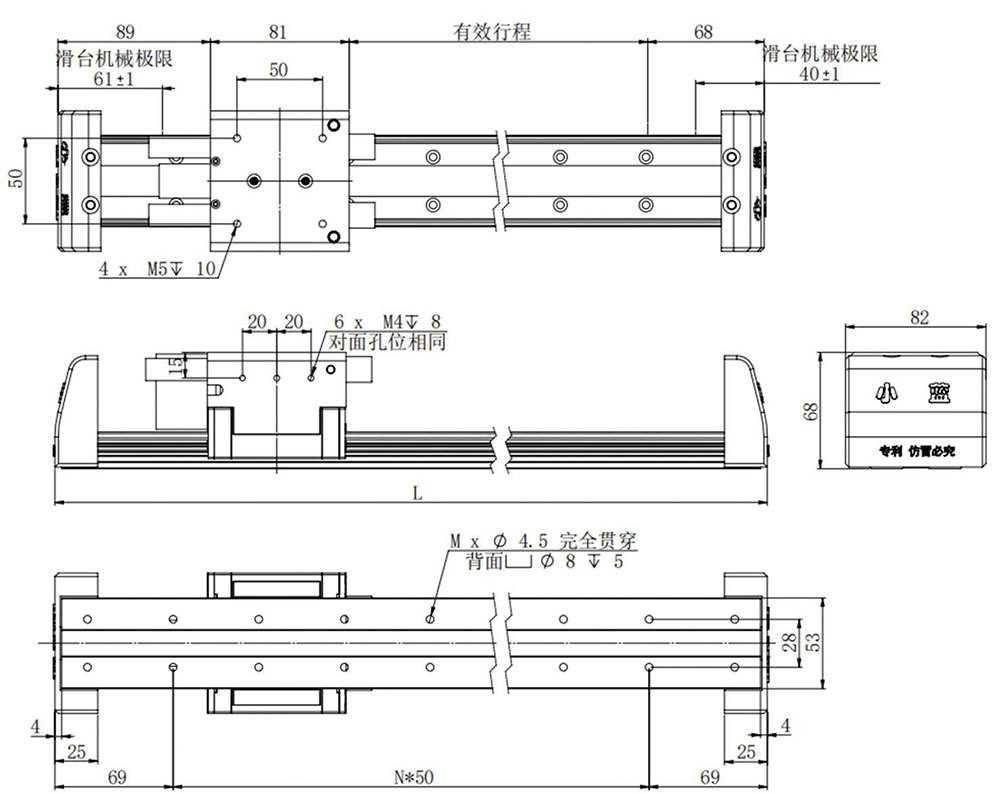

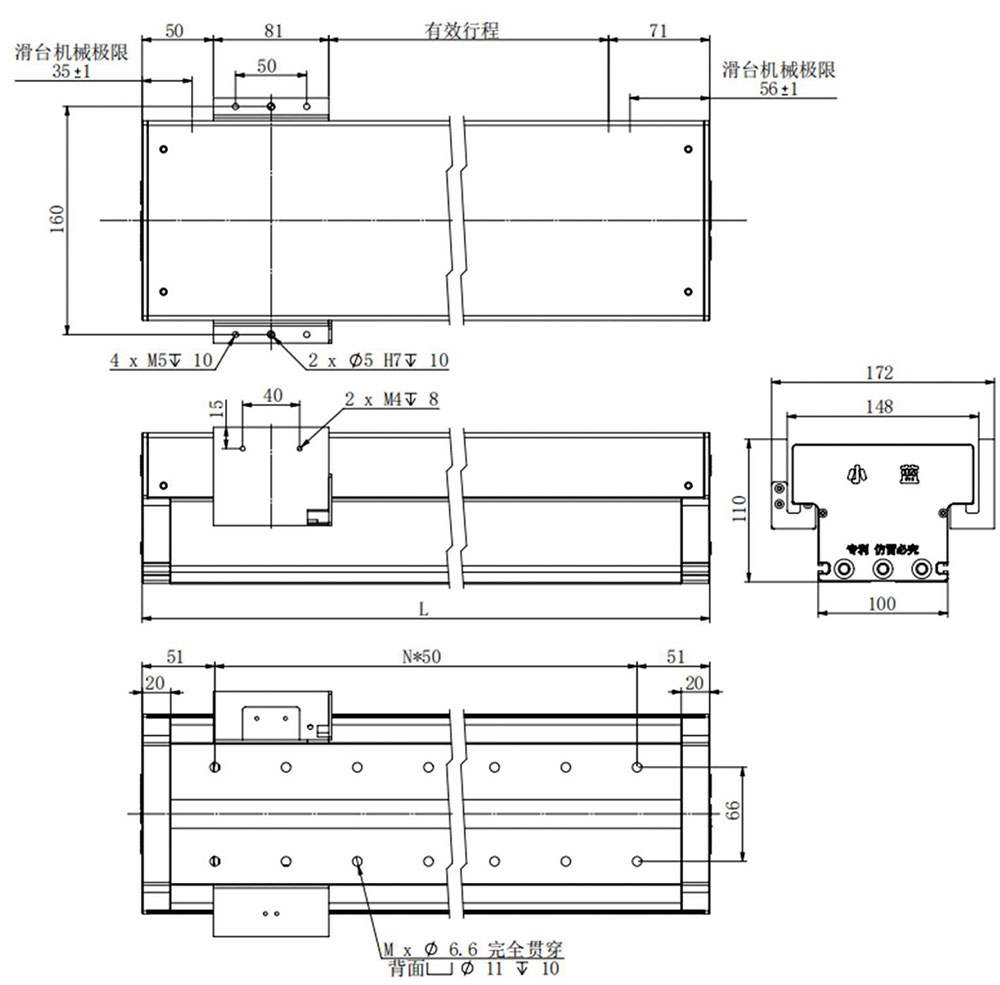

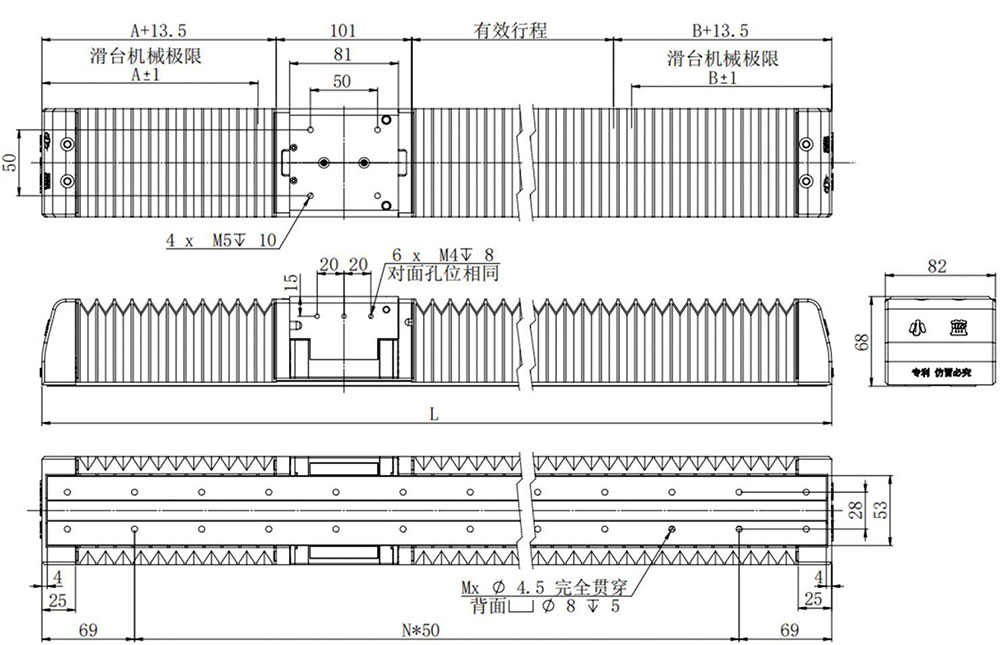

POWER RAIL standard

PRAC Series

POWR RAIL cover plate

PRGC Series

POWER RAIL Organ shield

PRBC Series

PRAC03

Parameters

| Item | Symbol | Unit | PR31-H |

|---|---|---|---|

| Continuous thrust | Fe | N | 35 |

| Continuous current | Ic | Arms | 1.5 |

| Instantaneous thrust [1s] | Fp | N | 70 |

| Instantaneous current [1s] | Ip | Arms | 3.1 |

| Thrust constant | Kf | N/Arms | 23.4 |

| Suction between stator and forcer | Fa | N | 150 |

| Max. coil temperature | Tmax | ℃ | 125 |

| Electrical time constant | Ke | ms | 5.5 |

| Resistance [between lines, 25℃] | R25 | R | 7.4 |

| Inductance [between lines] | L | Mn | 41 |

| Class distance | 2τ | mm | 24 |

| Motor wire winding radius | Rbend | mm | 40 |

| Counter EMF Constant | Kv | Vrms/[m/s] | 28 |

| Motor constant [between lines, 25°C] | Km | N2/W | 47 |

| Thermal resistance | RTH | ℃/W | 2.5 |

| Thermal Sensing Switch | - | - | PT100 (thermal resistor) |

| Max. operating voltage | V | VDC | 600 |

| Forcer mass | Mf | Kg | 1.719 |

| Forcer length | L | mm | 81 |

| Stator unit mass | Ms | Kg/m | 8.225 |

| Max. carrying weight | mmax | Ks | 2 |

| No-load top speed | Vmax | m/s | 4 |

| No-load Max. acceleration | amax | m/s2 | 25 |

Accuracy

| Category | Effective Stroke 100-1000 | Effective Stroke 1001-2000 | Effective Stroke 2001-3750 |

|---|---|---|---|

| YT1 | ±3 | ±3 | ±3 |

PRGC03

Parameters

| Item | Symbol | Unit | PR31-H |

|---|---|---|---|

| Continuous thrust | Fe | N | 35 |

| Continuous current | Ic | Arms | 1.5 |

| Instantaneous thrust [1s] | Fp | N | 70 |

| Instantaneous current [1s] | Ip | Arms | 3.1 |

| Thrust constant | Kf | N/Arms | 23.4 |

| Suction between stator and forcer | Fa | N | 150 |

| Max. coil temperature | Tmax | ℃ | 125 |

| Electrical time constant | Ke | ms | 5.5 |

| Resistance [between lines, 25℃] | R25 | R | 7.4 |

| Inductance [between lines] | L | Mn | 41 |

| Class distance | 2τ | mm | 24 |

| Motor wire winding radius | Rbend | mm | 40 |

| Counter EMF Constant | Kv | Vrms/[m/s] | 28 |

| Motor constant [between lines, 25°C] | Km | N2/W | 47 |

| Thermal resistance | RTH | ℃/W | 2.5 |

| Thermal Sensing Switch | - | - | PT100 (thermal resistor) |

| Max. operating voltage | V | VDC | 600 |

| Forcer mass | Mf | Kg | 2.719 |

| Forcer length | L | mm | 81 |

| Stator unit mass | Ms | Kg/m | 8.225 |

| Max. carrying weight | mmax | Ks | 1 |

| No-load top speed | Vmax | m/s | 4 |

| No-load Max. acceleration | amax | m/s2 | 15 |

Accuracy

| Category | Effective Stroke 100-1000 | Effective Stroke 1001-2000 | Effective Stroke 2001-3750 |

|---|---|---|---|

| YT1 | ±3 | ±3 | ±3 |

PRBC03

Parameters

| Item | Symbol | Unit | PR31-H |

|---|---|---|---|

| Continuous thrust | Fe | N | 35 |

| Continuous current | Ic | Arms | 1.5 |

| Instantaneous thrust [1s] | Fp | N | 70 |

| Instantaneous current [1s] | Ip | Arms | 3.1 |

| Thrust constant | Kf | N/Arms | 23.4 |

| Suction between stator and forcer | Fa | N | 150 |

| Max. coil temperature | Tmax | ℃ | 125 |

| Electrical time constant | Ke | ms | 5.5 |

| Resistance [between lines, 25℃] | R25 | R | 7.4 |

| Inductance [between lines] | L | Mn | 41 |

| Class distance | 2τ | mm | 24 |

| Motor wire winding radius | Rbend | mm | 40 |

| Counter EMF Constant | Kv | Vrms/[m/s] | 28 |

| Motor constant [between lines, 25°C] | Km | N2/W | 47 |

| Thermal resistance | RTH | ℃/W | 2.5 |

| Thermal Sensing Switch | - | - | PT100 (thermal resistor) |

| Max. operating voltage | V | VDC | 600 |

| Forcer mass | Mf | Kg | 1.8 |

| Forcer length | L | mm | 81 |

| Stator unit mass | Ms | Kg/m | 8.225 |

| Max. carrying weight | mmax | Ks | 2 |

| No-load top speed | Vmax | m/s | 4 |

| No-load Max. acceleration | amax | m/s2 | 20 |

Accuracy

| Category | Effective Stroke 100-1000 | Effective Stroke 1001-2000 | Effective Stroke 2001-2650 |

|---|---|---|---|

| YT1 | ±3 | ±3 | ±3 |

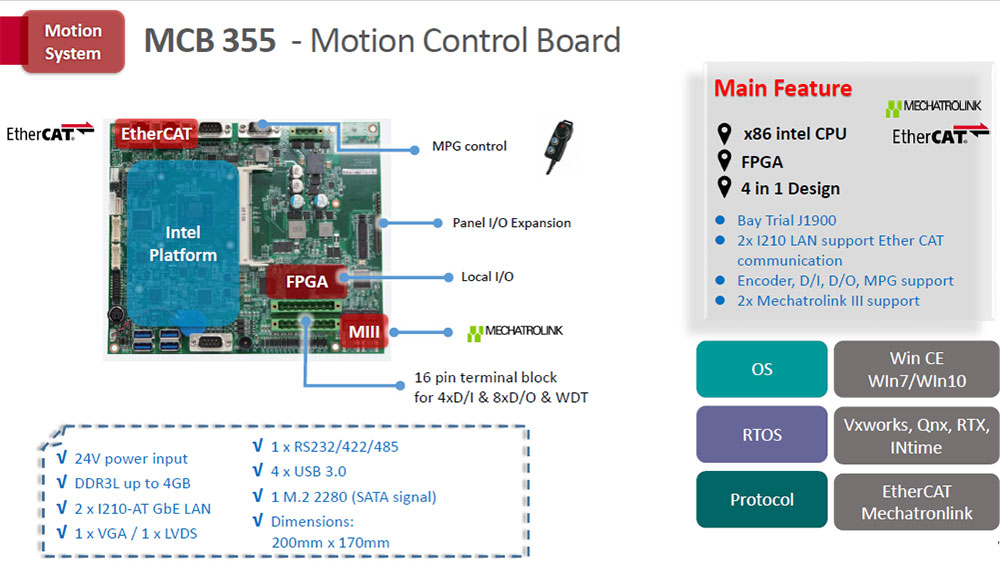

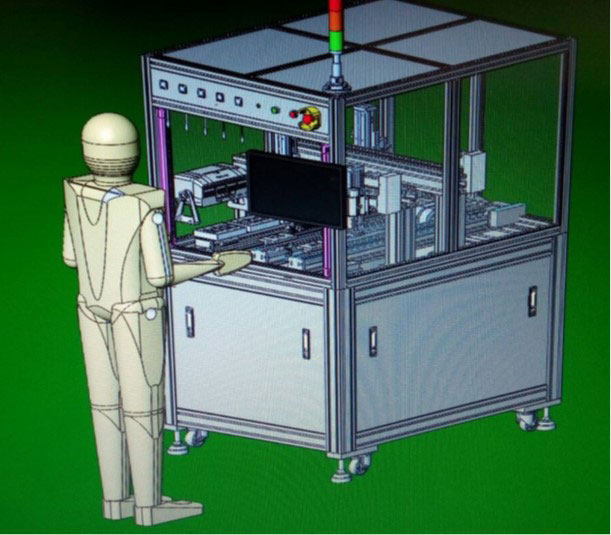

Automation & System Integration Specialized Equipment

Customized loading and unloading automation, high precision positioning platform mechanism design, combined with motion+ vision+ robots

Turnkey Solutions

Mechanical Design

Automation Mechanism

Design

High-precision

Positioning Platform Design

Control System

Mechanical

Vision

System

Motion

Integration

System

Electrical Control

Board

Design

Mechanical Design

automation

Mechanical Design

High-precision Positioning Platform Design

Control System

Mechanical Vision System

Motion Integration System

Electrical Control Board Design

High Precision-Linear Positioning Integration Performance

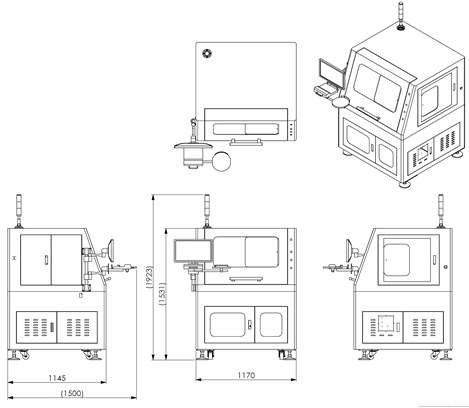

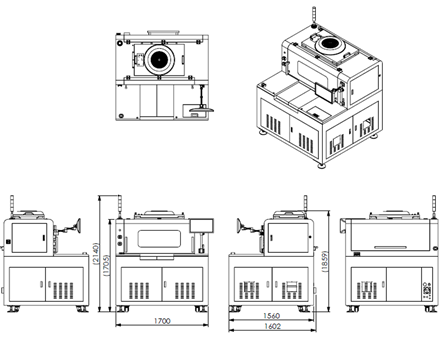

- Machine name: Laser Scribing Equipment (KF-XY-450-ROBOTSYSYTEM-CONTROLLER-K&Y)

- Work content: whole machine system integration (including mechanism, control, and distribution board)

Specification

| Load (Kg) | 15 |

|---|---|

| Stroke(mm) | X axis: 300 / Y axis: 150 |

| Max. acceleration (m/s*2) | 4.5 |

| Max. speed (m/s) | 0.45 |

| Repeatability (um) | ±0.5 |

| Absolute accuracy (um) | ±2 (after compensation) |

| Flatness (um) | 6 |

| Straightness(um) | 4 |

| Orthogonality (um) | 5 |

| Limit switch | NPN, NC, 12-24V |

| Installation direction | Horizontal |

| Linear motor model | X axis: PE-X4-W2 / Y axis: PB-X5-W1 |

| Continuous thrust (N) | X axis: 263.4 / Y axis: 134.8 |

| Max. thrust (N) | X axis: 1053.4 / Y axis: 539.2 |

| Optical encoder model | Renishaw RGH22, digital, 0.1um |

| Motion control card model | KFRM-4000-NX87 |

| IPC model | GTS-800-PG-VB-Laser |

| I/O expansion module model | ACC-S1616D |

| Drive model | GTHD-006-2AAP1(2PCS) |

| Screen model | ASUS 18.5” VS197TE |

| Keyboard model | WK590 mini keyboard USB |

| Mouse model | Microsoft basic optical USB mouse (warship black) |

- Machine name: Laser Drilling Equipment KF-X400-Y300-V350-ROBOTSYSTEM-0.1um

- Work content: whole machine system integration (including mechanism, control, and distribution board)

Specification

| Load (Kg) | 20 |

|---|---|

| Stroke(mm) | X axis:400 / Y axis:300 |

| Max. acceleration (m/s*2) | full stroke: 2.7 |

| Max. speed (m/s) | full stroke: 0.4 |

| Repeatability (um) | ±0.5 |

| Absolute accuracy (um) | 5(after compensation) |

| Flatness (um) | 8 |

| Straightness(um) | 8 |

| Orthogonality (um) | 10(300x300) |

| Limit switch | NPN, NC, 12-24V |

| Installation direction | Horizontal |

| Linear motor model | X axis:PE-X4-W2 / Y axis:PB-X5-W1 |

| Continuous thrust (N) | X axis:263.4 / Y axis:134.8 |

| Max. thrust (N) | X axis:1053.4 / Y axis:539.2 |

| Optical encoder model | Renishaw RGH28, digital, 0.1um |

| IPC model | KFRM-4000-NX87 |

| Motion control card model | GTS-400-PG-VB |

| I/O expansion module model | ACC-S1616D |

| Drive model | GTHD-006-2AAP1(2PCS) |

| Screen model | ASUS 18.5” VS197DE |

| Keyboard model | WK590 mini keyboard USB |

| Mouse model | Microsoft basic optical USB mouse (warship black) |

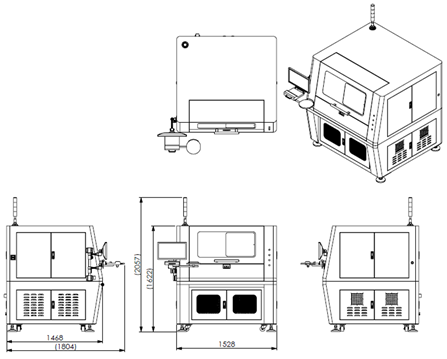

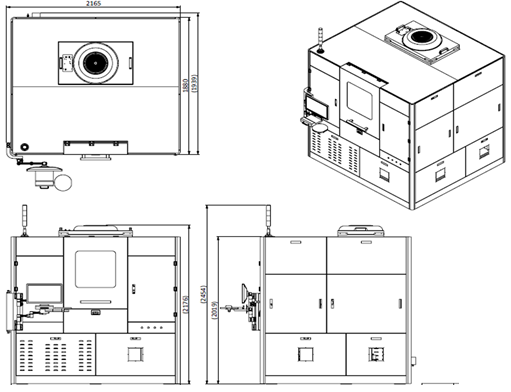

- Machine name: Laser Double-Platform Cutting Equipment KF-X800-V350-Y1-600-Y2-600-V450-BRIDGE- UV

- Work content: whole machine system integration (including mechanism, control, and distribution board)

Specification

| Load (Kg) | X axis:50 / Y1,Y2 axis:50 |

|---|---|

| Stroke(mm) | X axis:800 / Y1,Y2 axis:610 / Z axis:50 |

| Max. acceleration (m/s*2) | X axis:4.2 / Y1,Y2 axis:4.2 |

| Max. speed (m/s) | X axis:0.35 / Y1,Y2 axis:0.45 |

| Repeatability (um) | X axis:1 / Y1,Y2 axis:1 |

| Absolute accuracy (um) | X axis:8(after compensation)/ Y1,Y2 axis:5(after compensation) |

| Flatness (um) | X axis:15 / Y1,Y2 axis:10 |

| Straightness(um) | X axis:10 / Y1,Y2 axis:8 |

| Orthogonality (um) | 10(300x300) |

| Limit switch | Omron EE-SX674 |

| Installation direction | X axis:wall mount / Y1,Y2 axis:horizontal |

| Linear motor model | X axis:CB2-80-P / Y1,Y2 axis:CB4-60-SP |

| Continuous thrust (N) | X axis:301.3 / Y1,Y2 axis:396.5 |

| Max. thrust (N) | X axis:848.7 / Y1,Y2 axis:117.4 |

| Z axis motor model | Shihlin Electric, 400W with brake |

| Z-axis ballscrew lead (mm) | 2 |

| Optical encoder model | Renishaw RGH28, incremental digital, 0.1um |

| Motion control card model | GTS-400-PG-VB |

| I/O expansion module model | ACC-S1616D |

| Drive model | GTHD-006-2AAP1(3PCS) |

| Screen model | ASUS 18.5” VS197DE |

| Wireless keyboard& mouse model | Logitech MK240 Nano, black/yellow |

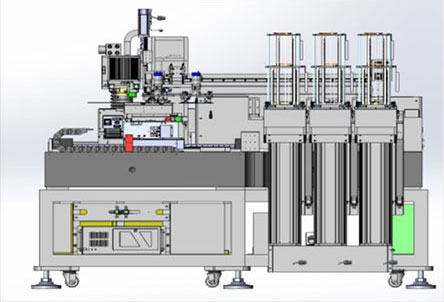

- Machine name: Soft Board Cutting Equipment KF-X700-Y930-V450-BRIDGE-ROBOTSYSTEM_S2S

- Work content: whole machine system integration (including mechanism, control, and distribution board)

Specification

| Load (Kg) | X axis:70 / Y axis:130 |

|---|---|

| Stroke(mm) | X axis:700 / Y axis:930 |

| Max. acceleration (m/s*2) | 4 (full stroke) |

| Max. speed (m/s) | 0.4 (full stroke) |

| Repeatability (um) | ±1 |

| Absolute accuracy (um) | ±2 ( after compensation ) |

| Flatness (um) | ±5 |

| Straightness(um) | ±5 |

| Orthogonality (um) | 10 |

| Settling time (ms) | 450/±5um |

| Installation direction | X axis:wall mount / Y axis:horizontal |

| Linear motor model | X axis:PD-X2-W2 / Y axis:PD-X4-W2 |

| Continuous thrust (N) | X axis:256.2 / Y axis:473.1 |

| Max. thrust (N) | X axis:1065 / Y axis:1892.3 |

| Optical encoder model | Renishaw RGH22, digital, 0.1um |

| Dust-proof way | X axis:metal cover / Y axis:Bellow dust-proof guard shield |

| Limit switch | Omron EE-SX674, EE-1010 |

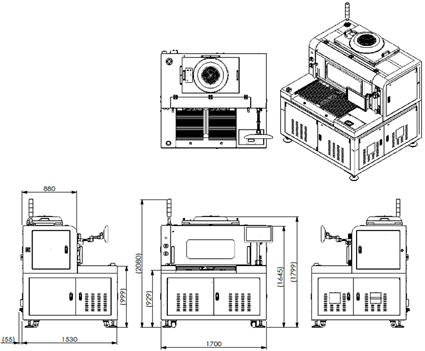

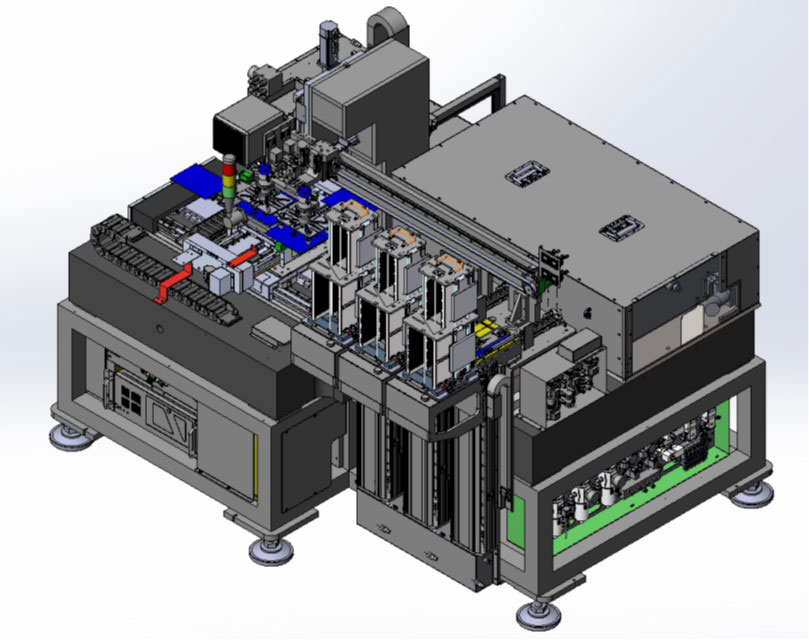

- Machine name: PICO IR Drilling and Scribing Equipment

- Work content: whole machine system integration (including mechanism, control, and distribution board)

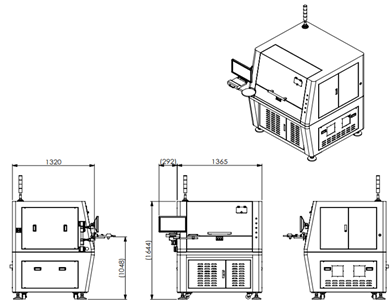

- Machine name: Laser Drilling& Scribing Equipment (CE compact new design) KF-X350-Y250-ROBOTSYSYTEM-Tonic

- Work content: whole machine system integration (including mechanism, control, and distribution board)

Specification

| Load (Kg) | 20 |

|---|---|

| Stroke(mm) | X axis:350 / Y axis:250 / Z axis:50 |

| Max. acceleration (m/s*2) | X axis:4(full stroke) / Y axis:4(full stroke) |

| Max. speed (m/s) | X axis:0.4(full stroke) / Y axis:0.4(full stroke) |

| Repeatability (um) | X. Y axis:±0.5 / Z axis:±5(single direction) |

| Absolute accuracy (um) | X. Y axis:±2.5(after compensation) |

| Flatness (um) | 8 |

| Straightness(um) | 8 |

| Orthogonality (um) | 10(300x250) |

| Limit switch | NPN, NC, 12-24V |

| Installation direction | Horizontal |

| Linear motor model | X axis:PE-X4-W2 / Y axis:PB-X5-W1 |

| Continuous thrust (N) | X axis:263.4 / Y axis:134.8 |

| Max. thrust (N) | X axis:1053.4 / Y axis:539.2 |

| Optical encoder model | Renishaw RELE20 (origin is 20mm from the edge), encoder body T1011**A+Ti 0200A20A-reading head+divider |

| Motion control card model | GTS-400-PG-VB |

| I/O expansion module model | ACC-S1616D |

| Drive model | GTHD-006-2AAP1 |

| Screen model | ASUS 18.5” VS197DE |

| Keyboard model | WK590 mini keyboard USB |

| Mouse model | Microsoft basic optical USB mouse (warship black) |

- Machine name: UV Fast Drilling Equipment KF-X550-V400-Y600-V400-BRIDGR-ROBOTSYSTEM

- Work content: whole machine system integration (including mechanism, control, and distribution board)

Specification

| Load (Kg) | X axis:20 / Y axis:10 |

|---|---|

| Stroke(mm) | X axis:550 / Y axis:610 / Z axis:50 |

| Max. acceleration (m/s*2) | X,Y axis:4(full stroke) |

| Max. speed (m/s) | X,Y axis:0.4(full stroke) |

| Repeatability (um) | X,Y axis:±1.5 / Z axis:±5 (single side) |

| Absolute accuracy (um) | X,Y axis:±2.5 (after compensation) |

| Flatness (um) | 10 |

| Straightness(um) | 10 |

| Orthogonality (um) | 10(300x300) |

| Limit switch | NPN, NC, 12-24V |

| Installation direction | X axis:side mount / Y axis:horizontal |

| Linear motor model | X axis:PE-X6-W2 / Y axis:PD-X2-W2 |

| Continuous thrust (N) | X axis:377.9 / Y axis:256.2 |

| Max. thrust (N) | X axis:1511.4 / Y axis:1025 |

| Optical encoder model | Renishaw RGH28, digital, 0.1um |

| Motion control card model | GTS-400-PG-VB |

| I/O expansion module model | ACC-S1616D |

| Drive model | GTHD-006-2AAP1 |

| Screen model | ASUS 18.5” VS197DE |

| Keyboard model | WK590 mini keyboard USB |

| Mouse model | Microsoft basic optical USB mouse (warship black) |

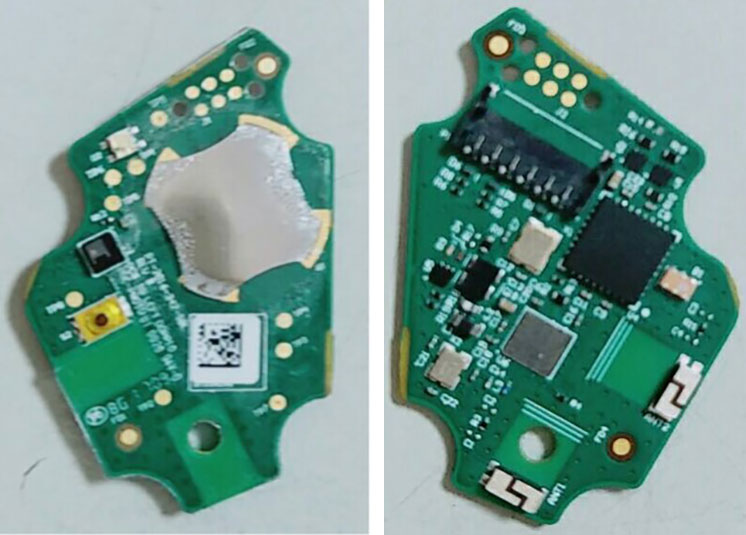

Non-Standard Automation Integration Performance

- Machine name: PCB mounter

- Main components: NIS-4U IPC/ Googoltech GTS-800-PG+GTS-400-PG

- Work content: whole machine system integration (including mechanism, control, vision, and distribution board)

- Machine name: Passive Component Packaging Equipment

- Explanation: Design the automatic equipment according to customer’s problems: productivity, fix the problems of the old equipment

- Benefit: Increase productivity

- Content: changes of the discharge track design for the vibrating plate& modular design changes for suction and discharge