GaN Lapping & Polishing

Trinity-Y

Gallium Nitride: Grinding, Lapping& CMP Machine

- Compact design, offering a space-saving concept for users to consolidate their processes into one system

- Designed to meet the growing demand for process applications of next generation materials for wide-gap semiconductors

- Multi-phased layout, offering flexibility to build a system that meets specific process needs

New Design and Technical Integration for an Advanced Wafer

Trinity-Y First

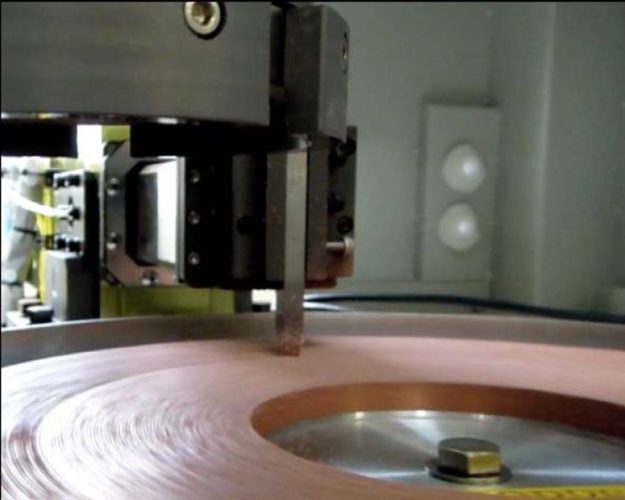

- Vertical Grinding Machine

- Lapping& Facing Machine

- CMP Machine

Trinity-Y EVG-200

Single Side Polishing System

EJ-380IY

Lapping and CMP Machine

Double Side Polishing System EJD-6B

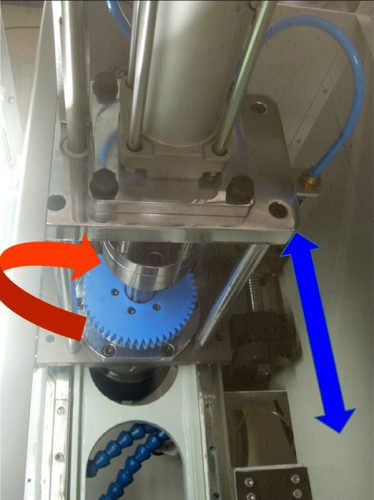

This upper and lower lapping plate rotate respectively in opposite direction. The carrier inserted between upper and lower lapping plates rotates in the same direction as lower lapping plate while revolving. The objects in the carrier are given movements to four directions.

Further, as the rotation ratio of upper and lower lapping plates and carrier are arranged in order to give equal lapping to both surfaces simultaneously, a very high lapping precision is acquired in short processing time.

Combined with other Trinity-Y equipment, it can save space and build high-efficiency processing system.

EJD-6BY Specifications

| Plate | OD 386mm x ID 148mm |

|---|---|

| Revolution | Max. 10~60 r.p.m. |

| Main Motor | 2.2kw 200V 3Phase |

| Drive System | 4 way 5work holding carrier |

| Upper Plate Control | Pneumatic Cylinder Φ125*400mm |

| Operation Panel | 7.4” Color LCD Touch Panel |

| Control System | PLC (Mitsubishi) |

| Program | Multi step program 5step |

| Number of Recipe | 10 recipe |

| Pressure Control | Counter pressure balance control |

| Facility requirement | Power : 200v 3 phase 30A Air : CDA 0.5Mpa |

| Dimension | 800 x 800 x 1920 (mm) |

Option

- Various Lapping Slurry

- Polishing Pad

- Pad Dresser

- Pad Conditioning Brush Carrier

- CMP Slurry Tank

- Slurry Cooling Unit (chiller)

- Grinding Plate

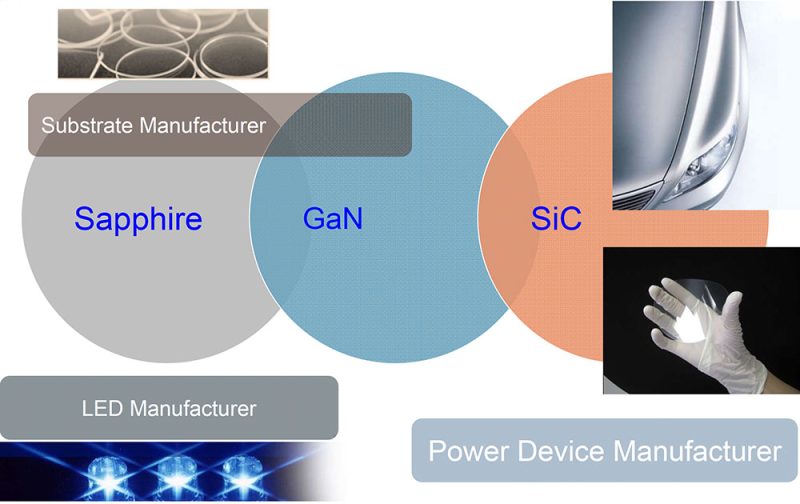

Advanced Material Industry Segments

Gallium Nitride Wafer 2 inch

| Substrate | 2 inch maximum |

|---|---|

| Thickness | 0.25~0.6mm |

| Substrate orientation | (0001) |

| Conduction Type | n-type |

| Carrier Concentration (cm-2) | typical 5 x1018 |

| Carrier Mobility (cm2/Vsec) | typical 170 |

| Resistivity (Ω/cm) | 8 x 10-3 |

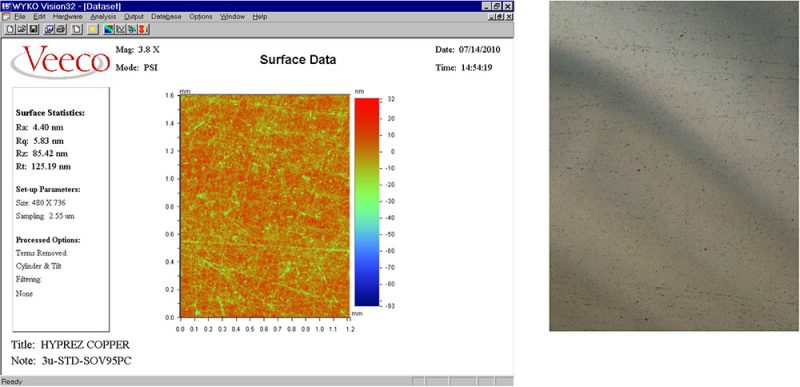

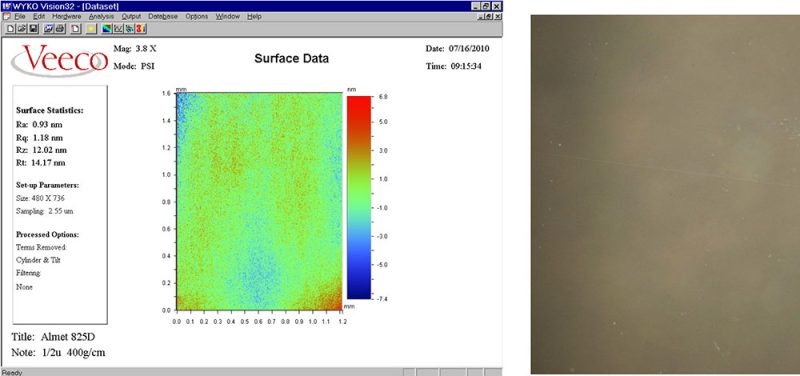

GaN Lapping Process

| Conditions | Step 1 | Step 2 | Step 3 |

|---|---|---|---|

| Machine | Trinity-Y EVG200TY | Trinity-Y EJW-380IF-TY | Trinity-Y EJW-380CMP-TY |

| Lap plate | MAD #8000 Wheel | Almet825 | ForGaN PAD |

| Plate speed | 1000 rpm/100 rpm | 60 rpm | 60 rpm |

| Plate cond. | Dressing block | Facing | ACR |

| Fixture | Ceramic plate φ138 Waxing | Ceramic plate φ138 Waxing | Ceramic plate φ138 Waxing |

| Condition ring | --- | --- | --- |

| Slurry | Coolant 81E | 1/2um-STD-LEDW | SP |

| Slurry supply | Circulation | Drip | Drip |

| Weight | --- | 20kg/3pcs | 15kg/3pcs |

| Lap time | 1st0.5u/min 2nd 0.3u/min | 30min | 6hr |

After Grinding Surface

After Lapping Surface

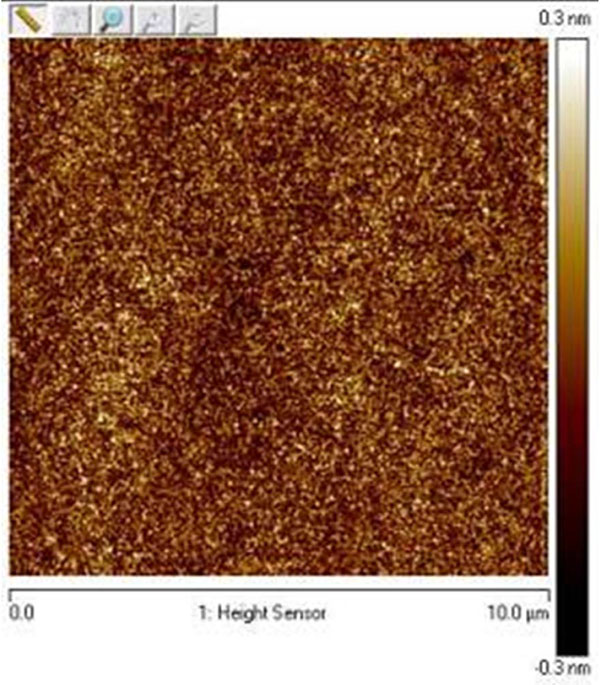

After CMP Surface